Smart Factory Automation: The Future of Manufacturing

Key Takeaways

- Intelligent factory automation integrates advanced technologies to boost manufacturing efficiency.

- IoT, AI, and robotics are some of the key technological advancements driving this transformation.

- Implementing automation increases productivity, reduces human error, and improves resource management.

- Sustainability and adaptability are becoming crucial factors in modern manufacturing processes.

Smart factory automation is revolutionizing manufacturing by integrating advanced technologies like AI, IoT, and robotics. These innovations enhance efficiency, reduce production costs, and improve product quality. Real-time data analytics and automated processes enable manufacturers to respond swiftly to market demands, driving the industry toward greater competitiveness and sustainability.

An Overview of Smart Factory Automation

In today’s rapidly evolving industrial landscape, factory automation solutions are revolutionizing manufacturing products. With the help of cutting-edge technology like robotics, artificial intelligence (AI), and the Internet of Things (IoT), this contemporary method creates production environments that are incredibly flexible and efficient. The concept of an intelligent factory is to seamlessly integrate machines, people, and data across the entire production line, resulting in increased efficiency and productivity.

Businesses work hard to implement these cutting-edge technologies to maintain competitiveness and satisfy the growing need for superior goods. By leveraging these technologies, factories can streamline operations and ensure higher precision and consistency. Smart factories can respond to market changes with agility, making them more resilient and versatile in the face of global challenges. As a result, adopting intelligent factory automation is becoming crucial for businesses aiming to stay ahead of the curve.

The Role of IoT in Manufacturing

Integrating IoT devices in manufacturing plants allows for real-time monitoring and data collection, enabling informed decision-making. Sensor networks and connected machinery allow communication across the entire production line, identifying potential issues before they become significant problems. This interconnected network reduces downtime and ensures equipment longevity. IoT systems optimize production processes, improve energy efficiency, and enhance product quality. Real-time insights allow for immediate adjustments, increased efficiency, and reduced waste. The data-driven approach ensures compliance with industry standards and regulations, promoting a more sustainable and transparent production environment.

AI: The Brain Behind Automation

AI algorithms transform manufacturing by analyzing vast factory floor data to optimize production processes. They can predict maintenance needs, streamline operations, and improve product quality. AI-driven insights help identify bottlenecks, optimize resource allocation, and reduce operational costs. Integrating AI in smart factories is not just about automation but also creating a more intelligent and adaptive manufacturing ecosystem. It can assist in quality control, demand forecasting, inventory management, and supply chain optimization, enabling manufacturers to respond more effectively to market demands. As Forbes reports, AI is set to become an integral part of the manufacturing sector in the coming years.

Robotics: Enhancing Productivity

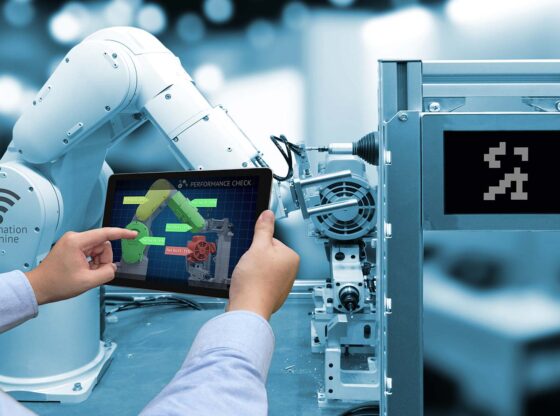

Advanced robotics is a critical component in intelligent factory automation, enhancing productivity by performing repetitive tasks with precision and speed. “Cobots,” or collaborative robots, operate alongside human employees to provide a more effective and safe work environment. These robots can do hazardous, dull, or extreme jobs, allowing human laborers to concentrate on more intricate production-related duties. Their versatility extends to assembly, welding, painting, and material handling, enabling consistent quality and reduced cycle times. Intelligent robots are becoming increasingly significant assets in a dynamic manufacturing environment because they can learn and adapt to new jobs. As robotics technology evolves, its impact on manufacturing efficiency and innovation will only grow.

Benefits of Implementing Smart Factory Automation

- Increased Productivity:Automation shortens the time and work involved in various production operations. Intelligent factories can fulfill the market’s increasing needs by producing more goods in less time by optimizing resource allocation and streamlining workflows.

- Reduced Human Error:Automated systems are less prone to errors than human-operated machines. This consistency ensures higher product quality and reduces the costs associated with rework and defects.

- Better Resource Management:Real-time data allows for efficient resource allocation and utilization. This optimization leads to cost savings and minimizes waste, contributing to more sustainable manufacturing practices.

- Enhanced Safety:Automation lowers the possibility of mishaps and injuries by delegating risky duties to robots. This protects workers and creates a safer and more pleasant working environment, enhancing employee satisfaction and productivity.

Adopting Sustainability in Smart Factories

Modern manufacturing focuses on sustainability by adopting energy-efficient technologies and reducing waste in intelligent factories. This includes renewable energy sources, waste recycling, and optimizing production processes. Cost savings and enhanced brand reputation are two benefits of adopting sustainable practices. Environmental effects are becoming more and more important to consumers. Therefore, manufacturers who prioritize sustainability can gain a competitive advantage. Intelligent factories may lessen their carbon footprint and support international efforts to tackle climate change by investing in green technologies. Adopting sustainability in intelligent factory automation is a trend and a necessary step toward a more responsible and resilient manufacturing industry.

Challenges in Smart Factory Implementation

Transitioning to a fully automated smart factory can be challenging due to high initial investments, cybersecurity threats, and the need for skilled personnel. The cost of implementing advanced technologies and upgrading existing infrastructure can be substantial, requiring careful planning and resource allocation. Integrating IoT and AI systems introduces new cybersecurity risks, requiring robust measures to protect networks and mitigate threats. Successful implementation requires a workforce with specialized data analysis, programming, and system integration skills. For personnel to be capable of operating and maintaining sophisticated automated systems, companies need to allocate resources toward training and development programs.

The Future of Factory Automation

Factory automation is expected to become more efficient and resilient, allowing factories to adapt quickly to changing market demands. Innovations like 5G connectivity, augmented reality, and digital twins are expected to enhance the capabilities of smart factories. 5G technology will provide faster, reliable communication, improving operational efficiency. Augmented reality will aid in training and maintenance, providing interactive experiences for workers. Digital twins will allow manufacturers to simulate and optimize production processes in a virtual environment. As these technologies become more accessible and affordable, the adoption of intelligent factory automation will continue to grow, shaping the future of manufacturing and driving industrial innovation.